Part Number: 79184129 / Vendor ID #: 1139477

PFERD 79184129

by PFERD

Call for Price

Item Sales Info

Add To Wishlist

Compare Item

Email

Print

Availability

- Manufacturer availability unknown.

Dimensions

Info & Guides

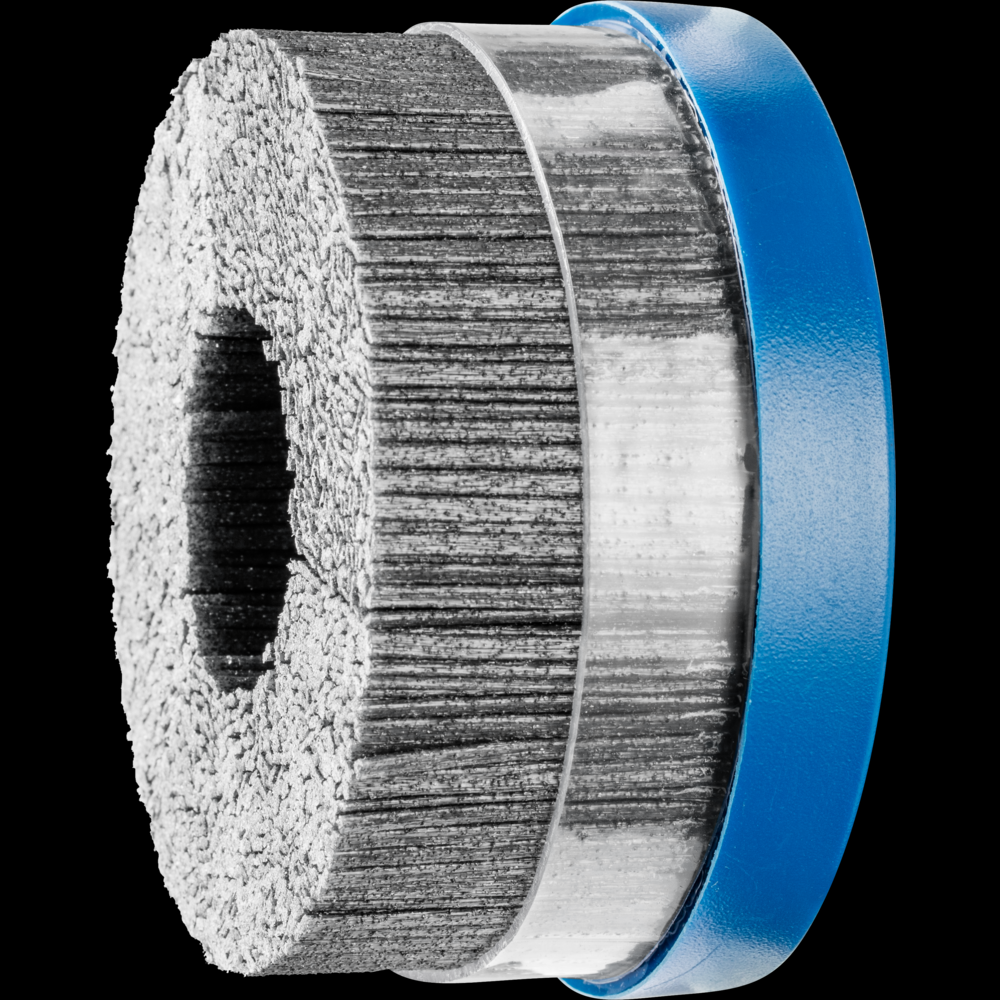

PFERD M-BRAD® Disc Brush 4" Dia. .045x.090/80 Grit Silicon Carbide 7/8" Arbor

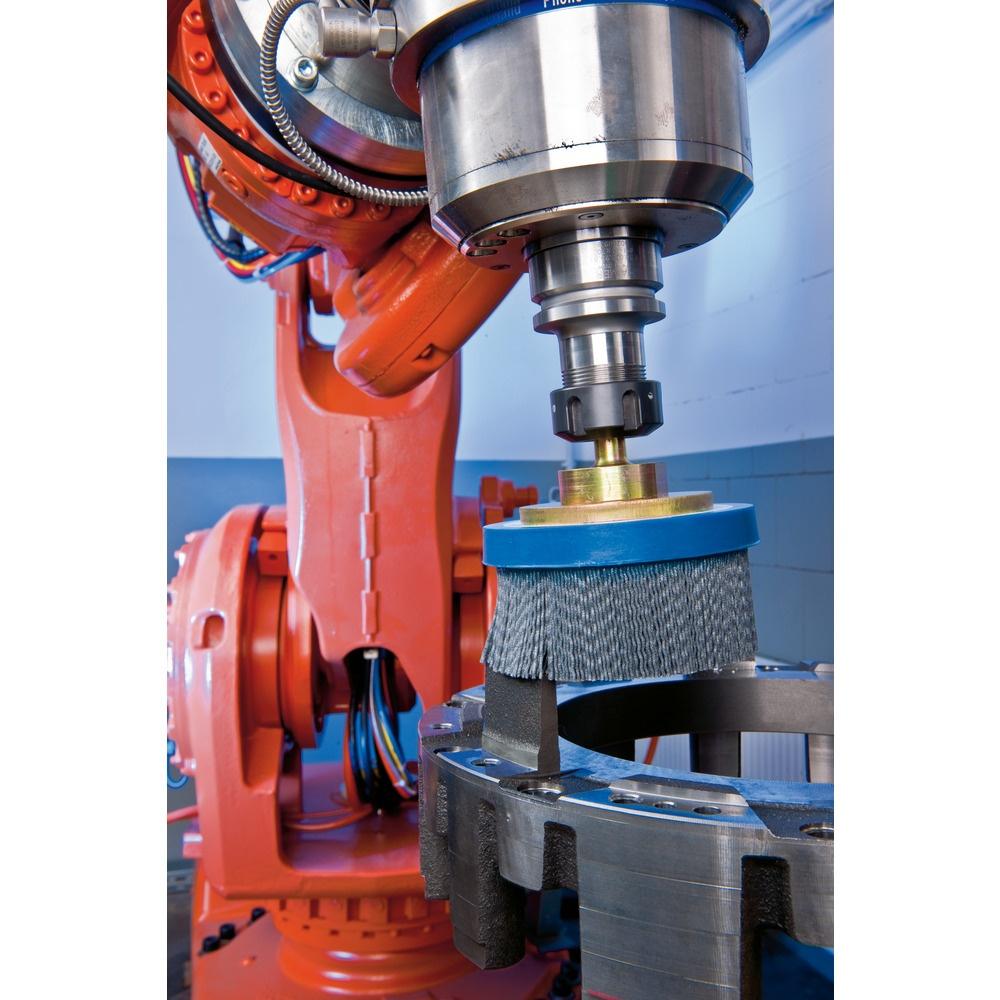

Particularly aggressive brush with bridle. Ideal for deburring and work on surfaces on stationary machines. Composite brushes from PFERD have been specifically developed for industrial, automated use. They are suitable for a variety of applications and their variable mounting options mean that they can be used on many different drive systems. This offers the advantage that the workpiece can be produced and finished on the same machine. As a result, labour-intensive, manual work is reduced and repeatable results are achieved with short cycle times. Silicon carbide (SiC) filament brushes are designed for deburring work and surface improvement. Rectangular filament [REC] is designed for particularly demanding applications that require an aggressive brush. The larger cross-section of the filaments means that these are more stiff than round filaments and provide a greater contact area with the workpiece. Platstic filaments are temperature-resistant up to 410°F.

Category:

Abrasives

Subcategory:

Abrasive Brushes and Wheel Kits

Subtype:

Disc Brushes

Advantages:

Long tool life and aggressive brushing action due to a very high filament density.

Advantages 1:

Extremely smooth operation due to evenly distributed filament material.

Advantages 2:

The bridle prevents the wires spreading out sideways.

Advantages 3:

If the filament has worn away down to the bridle, it can be removed from the bridle for further use. This does not affect the brushing behavior.

Advantages 4:

The bridle enables the spreading out and flexibility of the brush filament to be controlled.

Advantages 5:

Abrasive grains are embedded in flexible plastic filaments, which means that the filament works on the sides as well as at the tip.

Advantages 6:

For aggressive work due to rectangular filament (REC).

Applications:

Cleaning

Applications 1:

Deburring

Applications 2:

Roughening

Applications 3:

Structuring (matt finishing, brush matting and satin finishing)

CONTENT_UNIT:

C62

COUNTRY_OF_ORIGIN:

US

DEPTH:

0.111

Dia. external:

4

Dia. external UNIT:

Inch

Dia. filament material:

0.045

Dia. filament material UNIT:

Inch

Dia. hole:

7/8

Dia. hole UNIT:

Inch

Diam. arbor hole with adapter:

7/8

Diam. arbor hole with adapter UNIT:

Inch

Drive types:

Tool machine

Drive types 1:

Robot

Drive types 2:

Stationary machines

EAN pcs.:

4007220808740

EAN type:

AR

Filament material:

Silicon carbide (SiC)

Grit size:

80

Gross weight (Piece):

0.175

Gross weight (Piece) UNIT:

kg

Height (Packaging unit):

111

Height (Packaging unit) UNIT:

mm

INTERNATIONAL_PID (ean):

4007220808740

INTERNATIONAL_PID (edp):

84129

INTERNATIONAL_PID (gtin):

4007220808740

KEYWORD:

Industrial power brushes

KEYWORD 1:

Composite disc brushes

KEYWORD 2:

Crimped

KEYWORD 3:

COMPOSITE / with ring / with hole

LEADTIME:

3

LENGTH:

0.111

Length (Packaging unit):

111

Length (Packaging unit) UNIT:

mm

Length, filament to ring:

3/4

Length, filament to ring UNIT:

Inch

MANUFACTURER_NAME:

PFERD

MANUFACTURER_PID:

79184129

MANUFACTURER_TYPE_DESCR:

DBUR 100/22,2 REC SiC 80 1,14

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Bronze

Materials that can be worked 10:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 11:

Thermoplastics

Materials that can be worked 12:

Wood

Materials that can be worked 2:

Cast iron

Materials that can be worked 3:

Cast steel

Materials that can be worked 4:

Cobalt-based alloys

Materials that can be worked 5:

Thermosetting plastics

Materials that can be worked 6:

Other non-ferrous metals

Materials that can be worked 7:

Stainless steel (INOX)

Materials that can be worked 8:

Steel, cast steel

Materials that can be worked 9:

Steel materials with a hardness > 54 HRC

Mounting system:

Centre hole

NO_CU_PER_OU:

1

Ordering notes:

This composite disc brush comes with two drive pin holes with a 1/4" diameter.

ORDER_UNIT:

C62

Output name <= 80 characters:

PFERD M-BRAD® Disc Brush 4" Dia. .045x.090/80 Grit Silicon Carbide 7/8" Arbor

PFERDEFFICIENCY:

PFERDEFFICIENCY recommends composite brushes to achieve maximum stock removal as quickly as possible.

PFERDERGONOMICS:

PFERDERGONOMICS recommends composite brushes to sustainably reduce the vibrations produced during use.

Product issue name web for bmecat:

Composite disc brushes crimped Composite, with bridle, with hole

PRODUCT_ORDER:

20

prop65:

Warning: Cancer -- www.P65Warnings.ca.gov

QUANTITY_INTERVAL:

1

QUANTITY_MIN:

1

Recommendations for use:

Please observe the recommended rotational speeds.

Recommendations for use 1:

Use coolant for applications where large amounts of heat are produced.

Recommendations for use 2:

Remove the bridle once the filament is worn down. Then the rest of the filament can be used.

Recommendations for use 3:

Remove the bridle before starting work if you would like to achieve a large spreading diameter or access hard-to-reach areas.

REFERENCE_FEATURE_GROUP_ID:

P_16318_184867

RPM, max.:

3500

RPM, max. UNIT:

RPM

RPM, optimum, from:

1400

RPM, optimum, from UNIT:

RPM

RPM, optimum, to:

2300

RPM, optimum, to UNIT:

RPM

SPECIAL_TREATMENT_CLASS:

Warning: Cancer -- www.P65Warnings.ca.gov

TIME_BASE:

dayofweek

TIME_VALUE_END:

5

TIME_VALUE_START:

1

Trim length:

1 1/2

Trim length UNIT:

Inch

UNSPSC 25.0901:

31191521

UPC pcs.:

0

VOLUME:

0.000847

Volume (Packaging unit):

847

Volume (Packaging unit) UNIT:

CCM

WEIGHT:

0.175

WIDTH:

0.111

Width (Packaging unit):

111

Width (Packaging unit) UNIT:

mm

Manufactured By:

PFERD