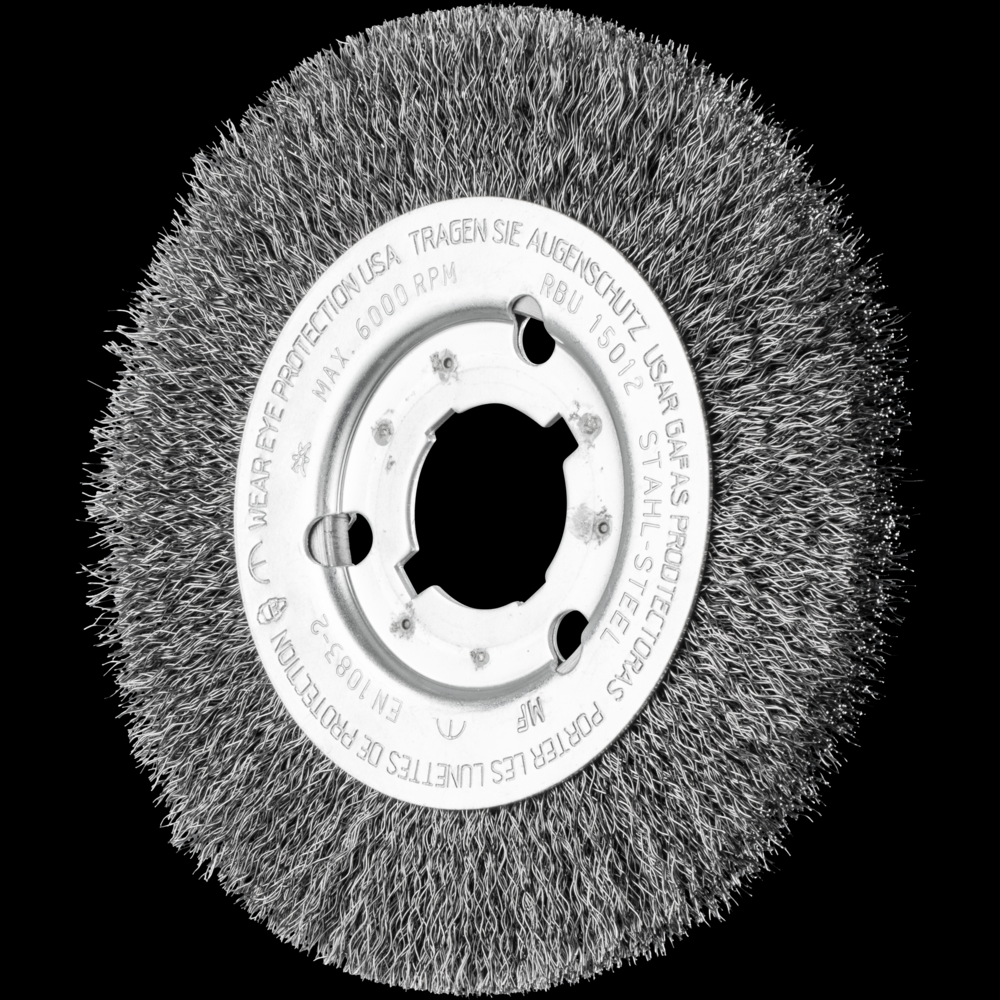

Part Number: 79180040 / Vendor ID #: 1139477

PFERD 79180040

by PFERD

Call for Price

Item Sales Info

Add To Wishlist

Compare Item

Email

Print

Availability

- Manufacturer availability unknown.

Dimensions

Info & Guides

PFERD Crimped Wire Wheel Brush 6" Dia Narrow Face .010 Carbon Steel 5/8-1/2" Arbor

Steel wire is the most common filament material. Brushes with steel wire as the filament material are ideal for work on surfaces and deburring. PFERD special wire has high tensile strength and bending fatigue strength. This ensures that the wire wears down in the optimal way, as well as a long tool life, even in extreme brushing applications. Steel wire is temperature-resistant up to 600°F. Excellent for medium-duty hand-held or automated brushing of large workpieces.

Category:

Abrasives

Subcategory:

Abrasive Brushes and Wheel Kits

Subtype:

Wire Wheel Brushes

Advantages:

Can be used with all common stationary drive systems and bench grinders.

Advantages 1:

The special design enables bunching to create wide gapless rollers. This enables a uniform surface finish to be achieved.

Advantages 2:

Highly flexible, enabling optimal adaptation to the workpiece contour.

Advantages 3:

Long service life through use of PFERD special wire.

Advantages 4:

Creates fine surfaces.

Applications:

Cleaning

Applications 1:

Deburring

Applications 2:

Derusting

Applications 3:

Removing oxide layers

Applications 4:

Paint stripping

Applications 5:

Roughening

CONTENT_UNIT:

C62

COUNTRY_OF_ORIGIN:

US

DEPTH:

0.229

Dia. external:

6

Dia. external UNIT:

Inch

Dia. filament material:

0.01

Dia. filament material UNIT:

Inch

Dia. hole:

1/2

Dia. hole UNIT:

Inch

Diam. arbor hole with adapter:

1/2

Diam. arbor hole with adapter UNIT:

Inch

Drive types:

Bench grinder

Drive types 1:

Flexible shaft drive

Drive types 2:

Straight grinder

EAN pcs.:

697940800403

Filament material:

Steel wire (ST)

Grit size:

No information

Gross weight (Piece):

0.393

Gross weight (Piece) UNIT:

kg

Height (Packaging unit):

229

Height (Packaging unit) UNIT:

mm

Installation width:

7/16

Installation width UNIT:

Inch

INTERNATIONAL_PID (edp):

80040

KEYWORD:

Industrial power brushes

KEYWORD 1:

Wheel brushes

KEYWORD 2:

Crimped

KEYWORD 3:

Slim / with hole

LEADTIME:

3

LENGTH:

0.331

Length (Packaging unit):

331

Length (Packaging unit) UNIT:

mm

MANUFACTURER_NAME:

PFERD

MANUFACTURER_PID:

79180040

MANUFACTURER_TYPE_DESCR:

WHL CRP NF 6X.010CSX5/8-1/2

Materials that can be worked:

Cast iron

Materials that can be worked 1:

Cast steel

Materials that can be worked 2:

Thermosetting plastics

Materials that can be worked 3:

Elastomers

Materials that can be worked 4:

Steel, cast steel

Materials that can be worked 5:

Steel materials with a hardness > 54 HRC

Materials that can be worked 6:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 7:

Thermoplastics

Materials that can be worked 8:

Wood

Mounting system:

Centre hole

NO_CU_PER_OU:

1

ORDER_UNIT:

C62

Output name <= 80 characters:

PFERD Crimped Wire Wheel Brush 6" Dia Narrow Face .010 Carbon Steel 5/8-1/2" Arbor

Product issue name web for bmecat:

Wheel brushes crimped slim, with hole

PRODUCT_ORDER:

110

prop65:

Warning: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov

QUANTITY_INTERVAL:

10

QUANTITY_MIN:

10

Recommendations for use:

Please observe the recommended rotational speeds.

REFERENCE_FEATURE_GROUP_ID:

P_16322_184973

RPM, max.:

8000

RPM, max. UNIT:

RPM

RPM, optimum, from:

4000

RPM, optimum, from UNIT:

RPM

RPM, optimum, to:

6000

RPM, optimum, to UNIT:

RPM

SPECIAL_TREATMENT_CLASS:

Warning: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov

TIME_BASE:

dayofweek

TIME_VALUE_END:

5

TIME_VALUE_START:

1

Trim length:

1 1/8

Trim length UNIT:

Inch

UNSPSC 25.0901:

27111907

UPC pcs.:

0

VOLUME:

0.011749

Volume (Packaging unit):

11749

Volume (Packaging unit) UNIT:

CCM

WEIGHT:

0.393

WIDTH:

0.155

Width:

5/8

Width (Packaging unit):

155

Width (Packaging unit) UNIT:

mm

Width UNIT:

Inch

Manufactured By:

PFERD