Return

Print

Email

Item Sales Info

PFERD 47901209

by PFERD

Call For Price

Call for Availability

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Qty

Product Overview

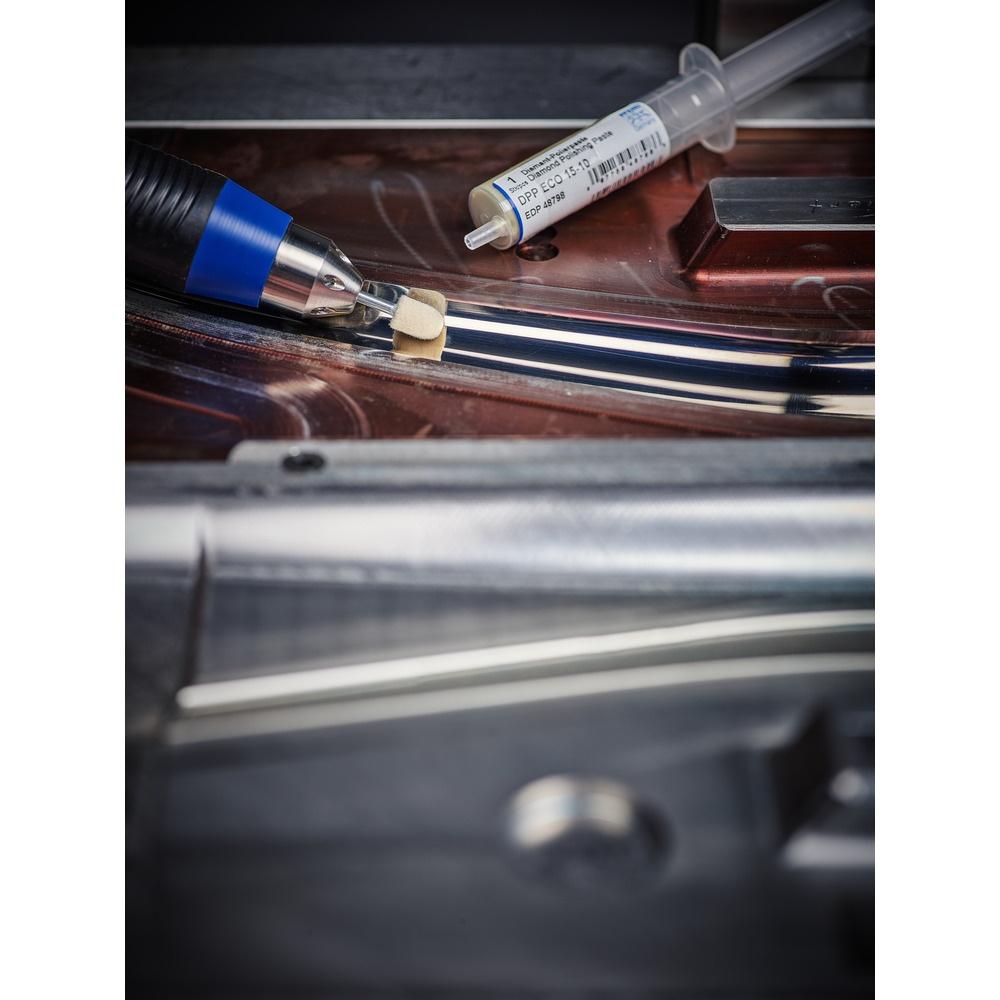

PFERD Felt Point, 3/8" x 9/16, Cylindrical Shape Radius End, Medium Grade, 1/8" Shank

Due to their hardness and flexibility, felt points are used when the exact form of geometric shapes has to be maintained. The cylindrical shape with radius end is mainly used for work on small, concave contours.

Product Availability

-

Item is usually in stock, but we'll be in touch if there's a problem

Info & Guides

Technical Details

Details

Advantages:

Can be freely shaped, meaning they can be used on complicated geometries.

Advantages 1:

Precise retention of geometric shapes due to the hardness of these products.

Applications:

Polishing

CONTENT_UNIT:

C62

COUNTRY_OF_ORIGIN:

DE

DEPTH:

0.049

Dia. external:

3/8

Dia. external UNIT:

Inch

Dia. shank:

1/8

Dia. shank UNIT:

Inch

Drive types:

Flexible shaft drive

Drive types 1:

Straight grinder

EAN pcs.:

4007220304327

EAN type:

AR

Gross weight (Piece):

0.004

Gross weight (Piece) UNIT:

kg

Height (Packaging unit):

49

Height (Packaging unit) UNIT:

mm

INTERNATIONAL_PID (ean):

4007220742037

INTERNATIONAL_PID (edp):

48631

INTERNATIONAL_PID (gtin):

4007220742037

INTERNATIONAL_PID (upc):

97758486316

KEYWORD:

Polishing tools

KEYWORD 1:

Felt points

KEYWORD 2:

M (medium) version

LEADTIME:

3

LENGTH:

0.063

Length (Packaging unit):

63

Length (Packaging unit) UNIT:

mm

Length, shank:

1 5/8

Length, shank UNIT:

Inch

MANUFACTURER_NAME:

PFERD

MANUFACTURER_PID:

47901209

MANUFACTURER_TYPE_DESCR:

FK WRC 1014/ 1/8

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Brass

Materials that can be worked 10:

Steel materials with a hardness > 54 HRC

Materials that can be worked 11:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 12:

Thermoplastics

Materials that can be worked 13:

Titanium

Materials that can be worked 14:

Titanium alloys

Materials that can be worked 2:

Bronze

Materials that can be worked 3:

Cast steel

Materials that can be worked 4:

Cobalt-based alloys

Materials that can be worked 5:

Copper

Materials that can be worked 6:

Fibre-reinforced thermosetting plastics (GRP, CRP)

Materials that can be worked 7:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 8:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Materials that can be worked 9:

Stainless steel (INOX)

NO_CU_PER_OU:

1

ORDER_UNIT:

C62

Output name <= 80 characters:

PFERD Felt Point, 3/8" x 9/16, Cylindrical Shape Radius End, Medium Grade, 1/8" Shank

Product issue name web for bmecat:

Felt points

PRODUCT_ORDER:

110

prop65:

Warning: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov

QUANTITY_INTERVAL:

10

QUANTITY_MIN:

10

Recommendations for use:

For the best performance, use with a recommended peripheral speed of 1,000-2,000 SFPM. This provides an ideal compromise between stock removal rate, surface quality, thermal load on the workpiece and tool wear.

Recommendations for use 1:

Use diamond polishing pastes and polishing paste bars.

Recommendations for use 2:

When applying a different polishing paste, use a new unused polishing product.

REFERENCE_FEATURE_GROUP_ID:

P_16035_179818

RPM, max.:

47500

RPM, max. UNIT:

RPM

RPM, optimum, from:

10000

RPM, optimum, from UNIT:

RPM

RPM, optimum, to:

20000

RPM, optimum, to UNIT:

RPM

Safety notes:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

SEGMENT:

Fine grinding and finishing products

Shape:

Cylindrical with radius end

SPECIAL_TREATMENT_CLASS:

Warning: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov

TIME_BASE:

dayofweek

TIME_VALUE_END:

5

TIME_VALUE_START:

1

UNSPSC 25.0901:

23131502

UPC pcs.:

0

UPC type:

UC

UPC VE:

97758486316

Version:

M (medium)

VOLUME:

6.5472e-005

Volume (Packaging unit):

65.472

Volume (Packaging unit) UNIT:

CCM

WEIGHT:

0.004

WIDTH:

0.049

Width:

9/16

Width (Packaging unit):

49

Width (Packaging unit) UNIT:

mm

Width UNIT:

Inch

Manufactured By:

PFERD