Return

Print

Email

PFERD 44692259 by PFERD

Call For Price

- Part Number: 44692259

- UPC:

- Availability: Loading Availability...

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

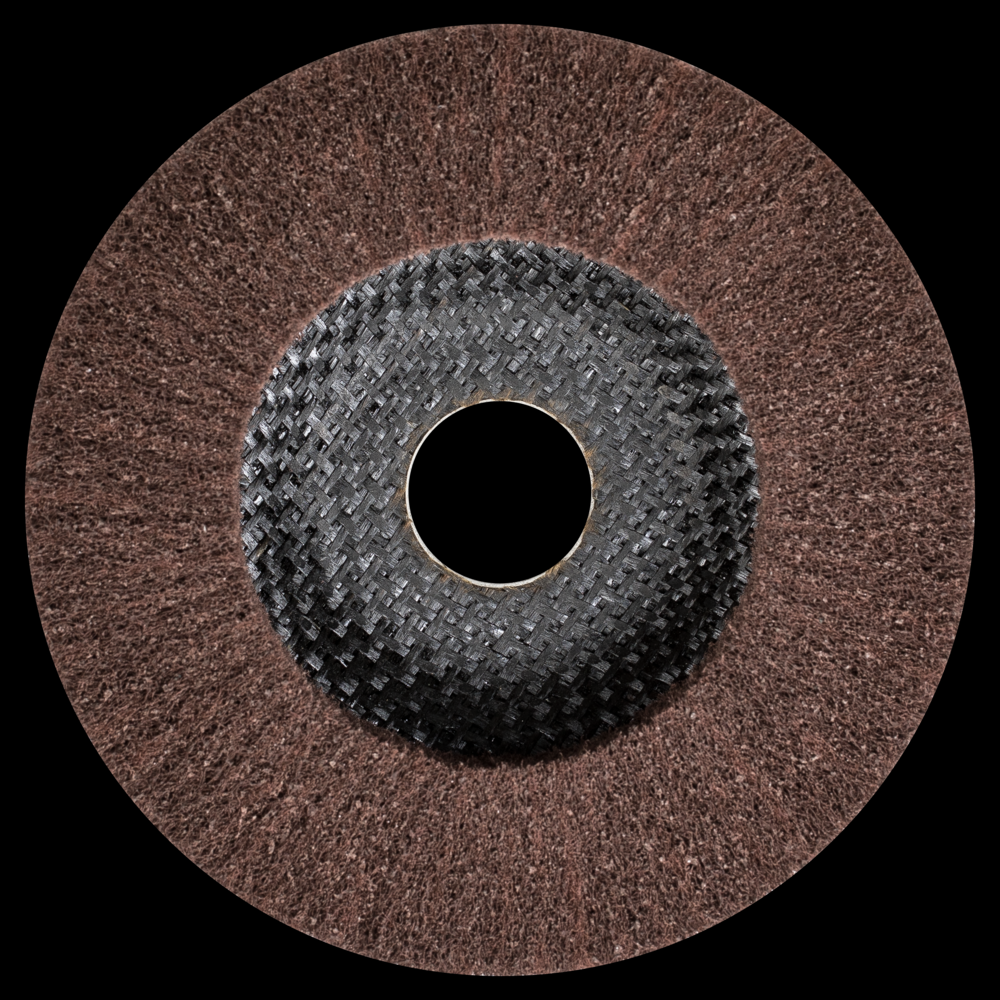

PFERD POLINOX® Fibre-backing disc, 4-1/2" 3/4 x 7/8, Radial, 180 Grit, Aluminum oxide

Long Description

POLINOX® grinding discs are made of non-woven polyamide abrasive, into which abrasive grain is integrated. The non-woven abrasive flaps are attached to a fiberglass backer, for face-down finishing work. Densely stacked flaps make the disc durable. The tool is designed for working on large surfaces with variable speed angle grinders.

Specifications

Details

Category:

Abrasives

Subcategory:

Deburring and Cleaning Tools

Subtype:

Deburring and Finishing Discs

Abrasive:

Aluminium oxide A

Advantages:

Conforms to contours due to high flexibility.

Advantages 1:

Cool grinding and low thermal load on the workpiece.

Advantages 2:

The open structure and high flexibility of the non-woven material prevents loading.

Applications:

Cleaning

Applications 1:

Deburring

Applications 2:

Step-by-step fine grinding

Applications 3:

Roughening

Applications 4:

Structuring (matt finishing, brush matting and satin finishing)

Applications 5:

Surface work

CONTENT_UNIT:

C62

COUNTRY_OF_ORIGIN:

DE

CUSTOMS_NUMBER:

6805301000

DEPTH:

0.137

Dia. external:

4 1/2

Dia. external UNIT:

Inch

Dia. hole:

7/8

Dia. hole UNIT:

Inch

Drive types:

Angle grinder

Drive types 1:

Cordless angle grinder

EAN pcs.:

4007220248591

EAN type:

AR

Grit size:

180

Gross weight (Piece):

0.1

Gross weight (Piece) UNIT:

kg

Height (Packaging unit):

137

Height (Packaging unit) UNIT:

mm

INTERNATIONAL_PID (ean):

4007220104231

INTERNATIONAL_PID (edp):

45892

INTERNATIONAL_PID (gtin):

4007220104231

INTERNATIONAL_PID (upc):

97758458924

KEYWORD:

Non-woven products

KEYWORD 1:

POLINOX® fibre-backing discs, radial construction

KEYWORD 2:

Aluminum oxide A

LEADTIME:

3

LENGTH:

0.261

Length (Packaging unit):

261

Length (Packaging unit) UNIT:

mm

MANUFACTURER_NAME:

PFERD

MANUFACTURER_PID:

44692259

MANUFACTURER_TYPE_DESCR:

PNL 115-22,23 A 180

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Brass

Materials that can be worked 10:

Steel materials with a hardness > 54 HRC

Materials that can be worked 11:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 12:

Thermoplastics

Materials that can be worked 13:

Titanium

Materials that can be worked 14:

Titanium alloys

Materials that can be worked 15:

Zinc

Materials that can be worked 2:

Bronze

Materials that can be worked 3:

Cast steel

Materials that can be worked 4:

Cobalt-based alloys

Materials that can be worked 5:

Copper

Materials that can be worked 6:

Fibre-reinforced thermosetting plastics (GRP, CRP)

Materials that can be worked 7:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 8:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Materials that can be worked 9:

Stainless steel (INOX)

NO_CU_PER_OU:

1

ORDER_UNIT:

C62

Output name <= 80 characters:

PFERD POLINOX® Fibre-backing disc, 4-1/2" 3/4 x 7/8, Radial, 180 Grit, Aluminum oxide

PFERDERGONOMICS:

PFERDERGONOMICS recommends POLINOX® grinding discs to reduce vibration and noise produced during use and to improve comfort when working.

Product issue name web for bmecat:

POLINOX discs PNL

PRODUCT_ORDER:

20

prop65:

Warning: Cancer -- www.P65Warnings.ca.gov

QUANTITY_INTERVAL:

5

QUANTITY_MIN:

5

Recommendations for use:

For the best performance, use with a recommended peripheral speed of 2,000-4,000 SFPM. This provides an ideal compromise between stock removal rate, surface quality, thermal load on the workpiece and flap wheel/cross buff wear.

REFERENCE_FEATURE_GROUP_ID:

P_16021_179788

RPM, max.:

5300

RPM, max. UNIT:

RPM

RPM, optimum:

2500

RPM, optimum UNIT:

RPM

Safety notes:

The maximum permitted peripheral speed is 6,300 SFPM.

Safety notes 1:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

SEGMENT:

Fine grinding and finishing products

SPECIAL_TREATMENT_CLASS:

Warning: Cancer -- www.P65Warnings.ca.gov

TIME_BASE:

dayofweek

TIME_VALUE_END:

5

TIME_VALUE_START:

1

UNSPSC 25.0901:

31191506

UPC pcs.:

0

UPC type:

UC

UPC VE:

97758458924

VOLUME:

0.002864

Volume (Packaging unit):

2864

Volume (Packaging unit) UNIT:

CCM

WEIGHT:

0.1

WIDTH:

0.137

Width:

3/4

Width (Packaging unit):

137

Width (Packaging unit) UNIT:

mm

Width UNIT:

Inch

Manufactured By:

PFERD