Return

Print

Email

PFERD 21728023 by PFERD

Call For Price

- Part Number: 21728023

- UPC:

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

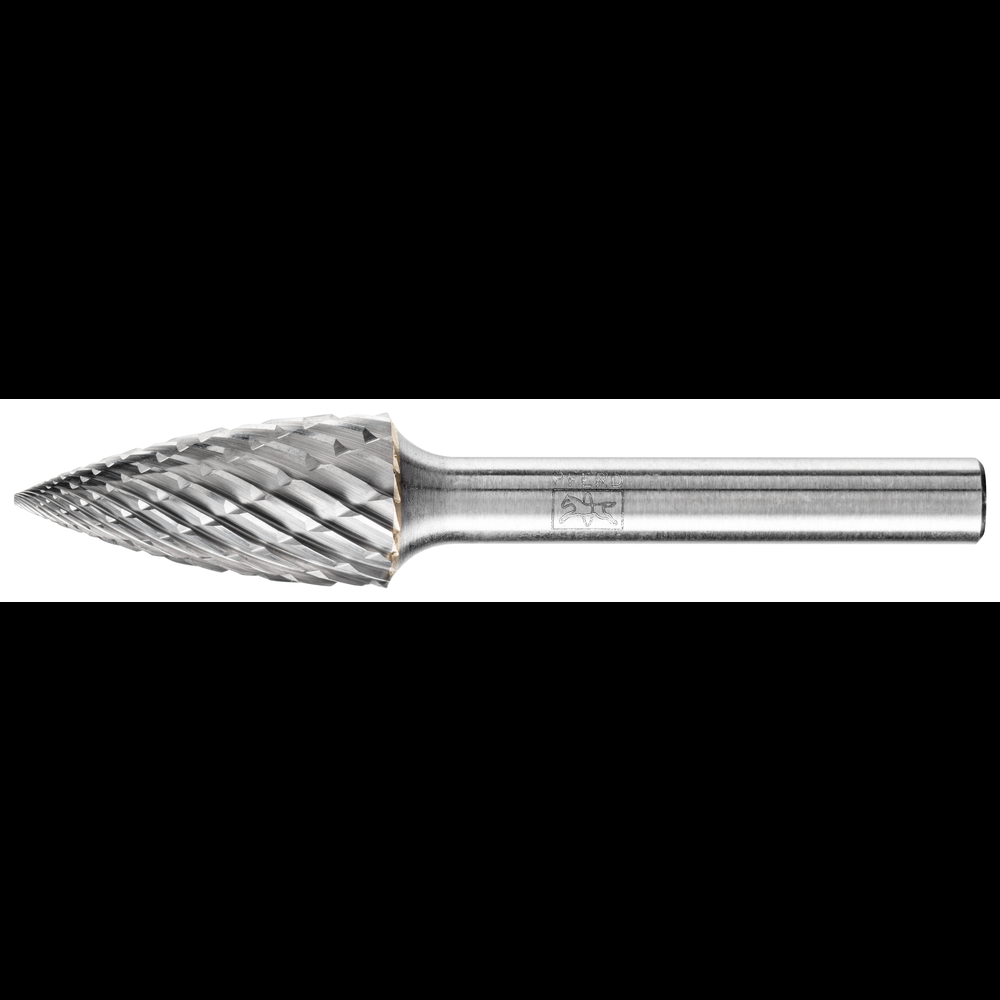

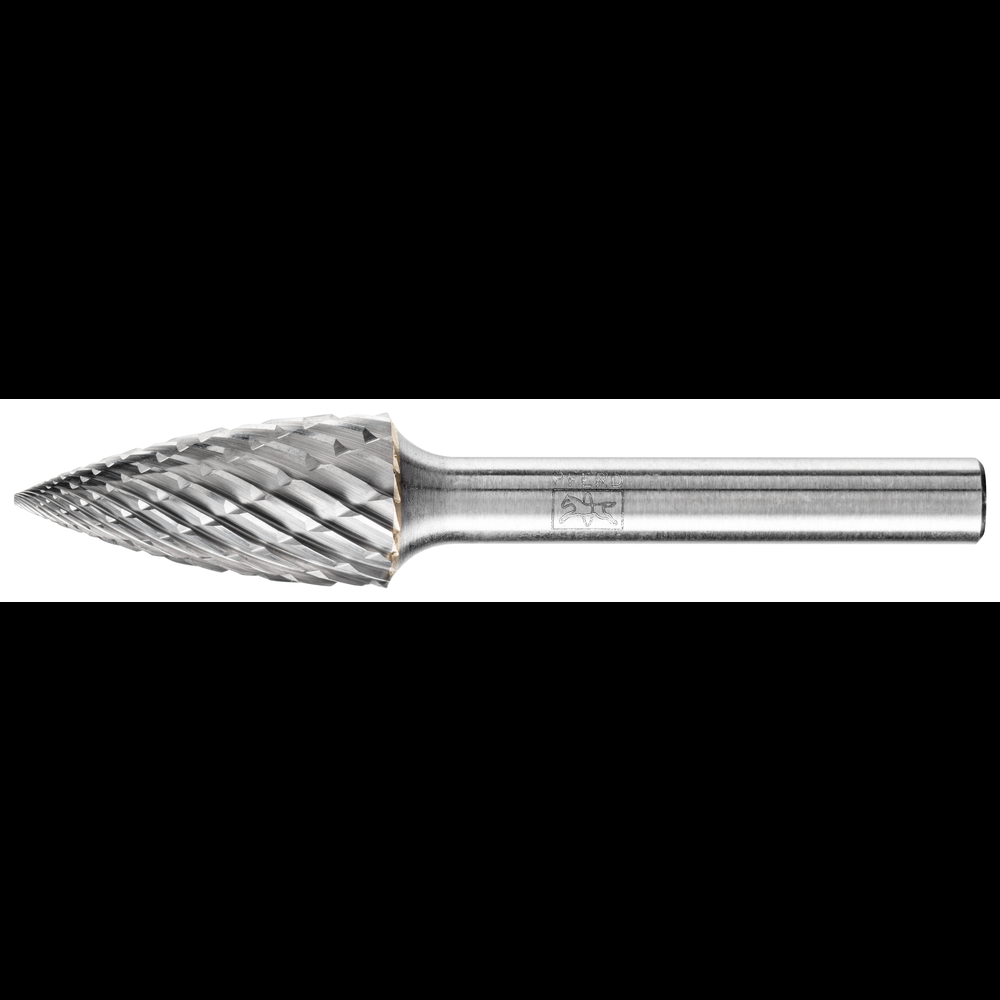

PFERD Carbide Bur SG-5 L6 Pointed Tree Shape OMNI Double Cut 1/2" x 1" x 1/4" Shank

Long Description

With the innovative OMNI cut, PFERD has developed unique burs for versatile use on key materials such as steel and cast steel, stainless steel (INOX), non-ferrous metals and cast iron. The OMNI cut offers all the benefits of the tried-and-tested double cut, but its stock removal rate is up to 30% higher for steel. It enables comfortable working with reduced vibration and less noise. The OMNI cut also offers significant time savings and a high economic value. Tree bur with pointed end, shape G. Tungsten carbide burs with extended shanks are ideal for efficiently machining small, hard-to-reach areas. The shanks can be shortened if required. This bur has a long steel shank.

Specifications

Details

Category:

Abrasives

Subcategory:

Points & Burrs

Subtype:

Burrs

Advantages:

Significantly better stock removal rate than conventional double cut burs.

Advantages 1:

Saves time and money with very high stock removal rate on key materials.

Advantages 2:

Comfortable working with reduced vibration and less noise.

Advantages 3:

The highly accurate concentricity enables precise work free from chatter marks. This considerably reduces wear on the bur and power tool or machine.

Applications:

Cutting out holes

Applications 1:

Deburring

Applications 2:

Leveling

Applications 3:

Milling

Applications 4:

Milling out

Applications 5:

Surface work

Applications 6:

Work on weld seams

CONTENT_UNIT:

C62

COUNTRY_OF_ORIGIN:

DE

Cut:

OMNI

DEPTH:

0.018

Dia. external:

1/2

Dia. external UNIT:

Inch

Dia. shank:

1/4

Dia. shank UNIT:

Inch

Drive types:

Flexible shaft drive

Drive types 1:

Tool machine

Drive types 2:

Robot

Drive types 3:

Stationary machines

Drive types 4:

Straight grinder

EAN pcs.:

4007220141007

EAN type:

AR

Gross weight (Piece):

0.07

Gross weight (Piece) UNIT:

kg

Height (Packaging unit):

18

Height (Packaging unit) UNIT:

mm

INTERNATIONAL_PID (edp):

28023

INTERNATIONAL_PID (upc):

97758280235

KEYWORD:

Tungsten carbide burs

KEYWORD 1:

High-performance OMNI cut

KEYWORD 2:

Pointed tree shape SPG

LEADTIME:

3

LENGTH:

0.128

Length (Packaging unit):

128

Length (Packaging unit) UNIT:

mm

Length, cut:

1

Length, cut UNIT:

Inch

Length, shank:

6

Length, shank UNIT:

Inch

MANUFACTURER_NAME:

PFERD

MANUFACTURER_PID:

21728023

MANUFACTURER_TYPE_DESCR:

SPG 12,7x25,4x6,35-150 ALLROUND

Materials that can be worked:

Annealed cast iron

Materials that can be worked 1:

Black annealed cast iron (GTS, GJMB)

Materials that can be worked 10:

Hard non-ferrous metal

Materials that can be worked 11:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 12:

Soft non-ferrous metal

Materials that can be worked 13:

Stainless steel (INOX)

Materials that can be worked 14:

Steel

Materials that can be worked 15:

Steel, cast steel

Materials that can be worked 16:

Steel materials with a hardness > 54 HRC

Materials that can be worked 17:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 18:

Steels over 220 HV (> 95 HB)

Materials that can be worked 19:

Steels up to 220 HV (< 95 HB)

Materials that can be worked 2:

Brass

Materials that can be worked 20:

Titanium

Materials that can be worked 21:

Titanium alloys

Materials that can be worked 22:

Tool steels

Materials that can be worked 23:

White annealed cast iron (GTW, GJMW)

Materials that can be worked 24:

Zinc

Materials that can be worked 3:

Bronze

Materials that can be worked 4:

Case-hardened steels

Materials that can be worked 5:

Cast iron

Materials that can be worked 6:

Cast steel

Materials that can be worked 7:

Copper

Materials that can be worked 8:

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Materials that can be worked 9:

Hard aluminium alloys

NO_CU_PER_OU:

1

ORDER_UNIT:

C62

Output name <= 80 characters:

PFERD Carbide Bur SG-5 L6 Pointed Tree Shape OMNI Double Cut 1/2" x 1" x 1/4" Shank

Overall length:

6 7/8

Overall length UNIT:

Inch

PFERDEFFICIENCY:

PFERDEFFICIENCY recommends OMNI cut burs for preventing fatigue, saving resources, and producing excellent work.

PFERDERGONOMICS:

PFERDERGONOMICS recommends OMNI cut burs as an innovative solution for comfortable working and significantly reduced vibration and noise.

Product issue name web for bmecat:

High-performance tungsten carbide burs, OMNI double cut, Tree bur with pointed end - Shape G

prop65:

Warning: Cancer -- www.P65Warnings.ca.gov

QUANTITY_INTERVAL:

1

QUANTITY_MIN:

1

Recommendations for use:

Use the burs on powerful power tools with elastically mounted spindles to avoid unwanted vibration.

Recommendations for use 1:

Observe the recommended rotational speed.

Recommendations for use 2:

The smaller the bur diameter is in the area being used, the higher the recommended rotational speed can be.

Recommendations for use 3:

For the most cost-effective bur use, work with higher rotational/peripheral speeds. For burs with a 1/4" shank diameter, use power tools with a power output from 300 watts.

REFERENCE_FEATURE_GROUP_ID:

P_15244_178394

RPM from, grey cast iron, white cast iron:

12000

RPM from, grey cast iron, white cast iron UNIT:

RPM

RPM from, hard non-ferrous metals:

12000

RPM from, hard non-ferrous metals UNIT:

RPM

RPM from, hardened, heat-treated steels over 370 H:

3000

RPM

RPM from, rust and acid-resistant steels:

3000

RPM from, rust and acid-resistant steels UNIT:

RPM

RPM from, soft non-ferrous metals:

12000

RPM from, soft non-ferrous metals UNIT:

RPM

RPM from, steels up to 370 HV (38 HRC):

3000

RPM from, steels up to 370 HV (38 HRC) UNIT:

RPM

RPM to, grey cast iron, white cast iron:

24000

RPM to, grey cast iron, white cast iron UNIT:

RPM

RPM to, hard non-ferrous metals:

16000

RPM to, hard non-ferrous metals UNIT:

RPM

RPM to, hardened, heat-treated steels over 370 HV:

7000

RPM

RPM to, rust and acid-resistant steels:

7000

RPM to, rust and acid-resistant steels UNIT:

RPM

RPM to, soft non-ferrous metals:

20000

RPM to, soft non-ferrous metals UNIT:

RPM

RPM to, steels up to 370 HV (38 HRC):

7000

RPM to, steels up to 370 HV (38 HRC) UNIT:

RPM

Safety notes:

Very high speeds can cause discoloration on the shank. This does not constitute a safety risk.

Safety notes 1:

For safety reasons, the maximum application speeds with contact with the workpiece require a reduction in the recommended speed of tungsten carbide burs with standard shanks. Observe the reduced speeds outlined in the product details.

Safety notes 2:

When working with longer shanks, it is crucial that the bur is in contact with the workpiece (or inserted in the hole or slot to be machined) before the power tool is turned on. As a rule, the bur must remain in contact with the workpiece for as long as th

Safety notes 3:

Not designed for robotic or stationary applications due to risk of bending. Use only rigid clamping systems/power tools.

SCTI-No.:

SG-5L6

SEGMENT:

Milling, holemaking and deburring products

SPECIAL_TREATMENT_CLASS:

Warning: Cancer -- www.P65Warnings.ca.gov

TIME_BASE:

dayofweek

TIME_VALUE_END:

5

TIME_VALUE_START:

1

UNSPSC 25.0901:

23251706

UPC pcs.:

0

UPC type:

UC

UPC VE:

97758280235

VOLUME:

3.6703e-005

Volume (Packaging unit):

36.703

Volume (Packaging unit) UNIT:

CCM

WEIGHT:

0.07

WIDTH:

0.018

Width (Packaging unit):

18

Width (Packaging unit) UNIT:

mm

Manufactured By:

PFERD