Return

Print

Email

PFERD 21725143 by PFERD

Call For Price

- Part Number: 21725143

- UPC:

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

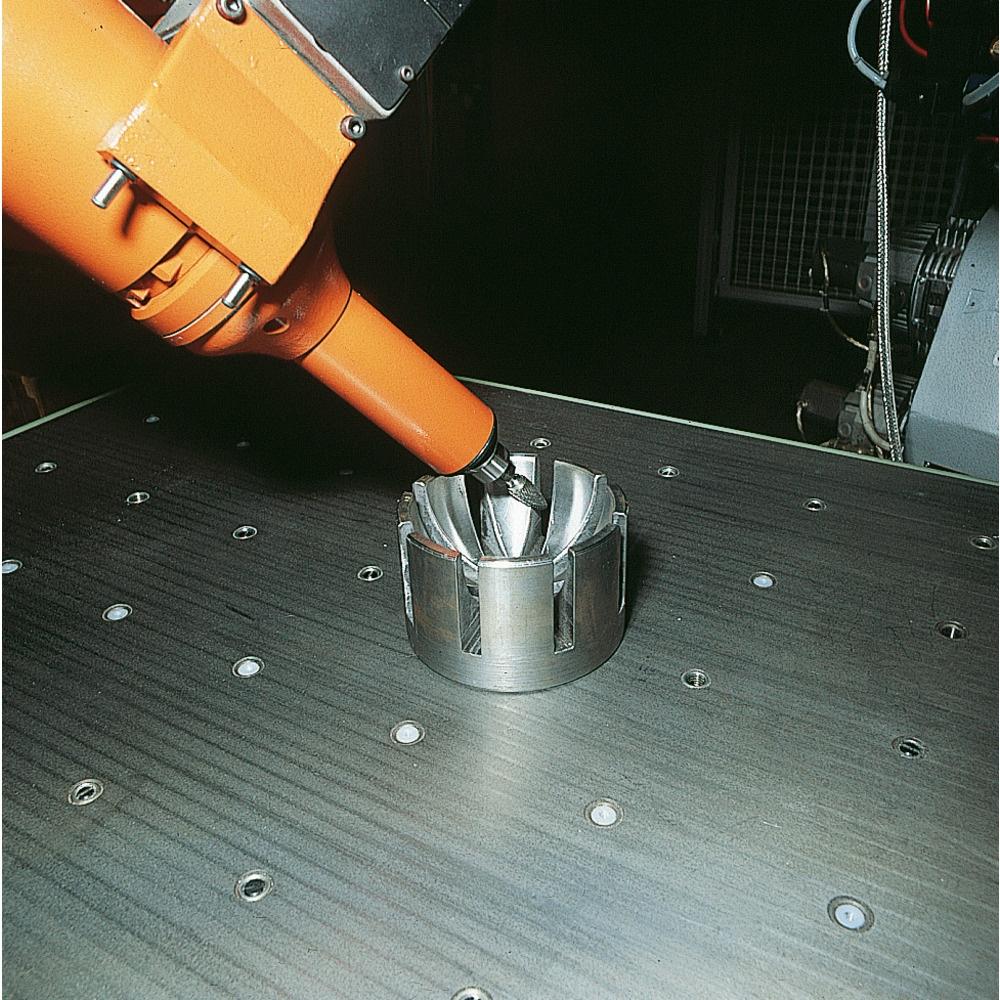

PFERD Carbide Bur SL-2 14° Taper Diamond Cut 5/16" x 7/8" x 1/4" Shank

Long Description

Diamond cut burs are designed for machining stainless steel (INOX), steel, and high-temperature-resistant materials such as nickel-based and cobalt-based alloys. They have high stock removal with short chips, and achieve a good surface finish. Universal line burs are designed for fine and coarse stock removal on the key materials used in industrial manufacturing. They provide a good stock removal rate and are not specific to a particular material. 14° Taper bur with round radius end, shape L.

Specifications

Details

Category:

Abrasives

Subcategory:

Points & Burrs

Subtype:

Burrs

Advantages:

Good stock removal rate due to high quality tungsten carbide, bur shape, cut, and optional coating.

Advantages 1:

Durable.

Advantages 2:

The highly accurate concentricity enables precise work free from chatter marks. This considerably reduces wear on the bur and power tool or machine.

Advantages 3:

High surface quality.

Angle:

16

Angle UNIT:

°

Applications:

Cutting out holes

Applications 1:

Deburring

Applications 2:

Leveling

Applications 3:

Milling

Applications 4:

Milling out

Applications 5:

Surface work

Applications 6:

Work on weld seams

CONTENT_UNIT:

C62

COUNTRY_OF_ORIGIN:

DE

CUSTOMS_NUMBER:

8207703030

Cut:

Diamond

DEPTH:

0.026

Dia. external:

5/16

Dia. external UNIT:

Inch

Dia. shank:

1/4

Dia. shank UNIT:

Inch

Drive types:

Flexible shaft drive

Drive types 1:

Tool machine

Drive types 2:

Robot

Drive types 3:

Stationary machines

Drive types 4:

Straight grinder

EAN pcs.:

4007220054413

EAN type:

AR

Gross weight (Piece):

0.028

Gross weight (Piece) UNIT:

kg

Height (Packaging unit):

26

Height (Packaging unit) UNIT:

mm

INTERNATIONAL_PID (edp):

25143

INTERNATIONAL_PID (upc):

97758251433

KEYWORD:

Tungsten carbide burs

KEYWORD 1:

Universal diamond cut

KEYWORD 2:

Conical shape with radius end, shape L

LEADTIME:

3

LENGTH:

0.103

Length (Packaging unit):

103

Length (Packaging unit) UNIT:

mm

Length, cut:

1

Length, cut UNIT:

Inch

MANUFACTURER_NAME:

PFERD

MANUFACTURER_PID:

21725143

MANUFACTURER_TYPE_DESCR:

KEL 8,3x25,8x6,35 C4

Materials that can be worked:

Bronze

Materials that can be worked 1:

Case-hardened steels

Materials that can be worked 10:

Steel

Materials that can be worked 11:

Steel, cast steel

Materials that can be worked 12:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 13:

Steels over 220 HV (> 95 HB)

Materials that can be worked 14:

Steels up to 220 HV (< 95 HB)

Materials that can be worked 15:

Titanium

Materials that can be worked 16:

Titanium alloys

Materials that can be worked 17:

Tool steels

Materials that can be worked 2:

Cast steel

Materials that can be worked 3:

Cobalt-based alloys

Materials that can be worked 4:

Hard aluminium alloys

Materials that can be worked 5:

Hard non-ferrous metal

Materials that can be worked 6:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 7:

High-temperature-resistant materials

Materials that can be worked 8:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Materials that can be worked 9:

Stainless steel (INOX)

NO_CU_PER_OU:

1

ORDER_UNIT:

C62

Output name <= 80 characters:

PFERD Carbide Bur SL-2 14° Taper Diamond Cut 5/16" x 7/8" x 1/4" Shank

Overall length:

2 13/16

Overall length UNIT:

Inch

Product issue name web for bmecat:

Tungsten carbide burs for versatile use, Diamond cut, 14° Taper bur with radius end – Shape L

prop65:

Warning: Cancer -- www.P65Warnings.ca.gov

QUANTITY_INTERVAL:

1

QUANTITY_MIN:

1

Radius:

0.049

Radius UNIT:

Inch

Recommendations for use:

The smaller the bur diameter is in the area being used, the higher the recommended rotational speed can be.

Recommendations for use 1:

For the most cost-effective bur use, work with higher rotational/peripheral speeds. For burs with a 1/4" shank diameter, use power tools with a power output from 300 watts.

REFERENCE_FEATURE_GROUP_ID:

P_15218_177579

RPM from, hard non-ferrous metals:

10000

RPM from, hard non-ferrous metals UNIT:

RPM

RPM from, hardened, heat-treated steels over 370 H:

10000

RPM

RPM from, high-temperature-resistant materials:

10000

RPM from, high-temperature-resistant materials UNI:

RPM

RPM from, rust and acid-resistant steels:

10000

RPM from, rust and acid-resistant steels UNIT:

RPM

RPM to, hard non-ferrous metals:

14000

RPM to, hard non-ferrous metals UNIT:

RPM

RPM to, hardened, heat-treated steels over 370 HV:

14000

RPM

RPM to, high-temperature-resistant materials:

18000

RPM to, high-temperature-resistant materials UNIT:

RPM

RPM to, rust and acid-resistant steels:

18000

RPM to, rust and acid-resistant steels UNIT:

RPM

SCTI-No.:

SL-2

SEGMENT:

Milling, holemaking and deburring products

SPECIAL_TREATMENT_CLASS:

Warning: Cancer -- www.P65Warnings.ca.gov

TIME_BASE:

dayofweek

TIME_VALUE_END:

5

TIME_VALUE_START:

1

UNSPSC 25.0901:

23251706

UPC pcs.:

0

UPC type:

UC

UPC VE:

97758251433

VOLUME:

5.1e-005

Volume (Packaging unit):

51

Volume (Packaging unit) UNIT:

CCM

WEIGHT:

0.028

WIDTH:

0.026

Width (Packaging unit):

26

Width (Packaging unit) UNIT:

mm

Manufactured By:

PFERD